Knowing that ultra-realism was key to securing interest for their customized 3D printed snow globes off their portfolio, Austrian 3D modeling, scanning, and printing specialist, Schiner 3D Repro, decided to invest in Stratasys J750 which has helped them to save up to 85% in production time compared to other methods.

Invented back in 1900 by Austrian Erwin Perzy, the snow globe has been ever-present as a popular gift and souvenir for many around the world. With Schiner 3D Repro long-standing expertise in using 3D printing technologies over traditional craftsmanship in producing their unique snow globes, the company invested in a J750 when it debuted in 2015.

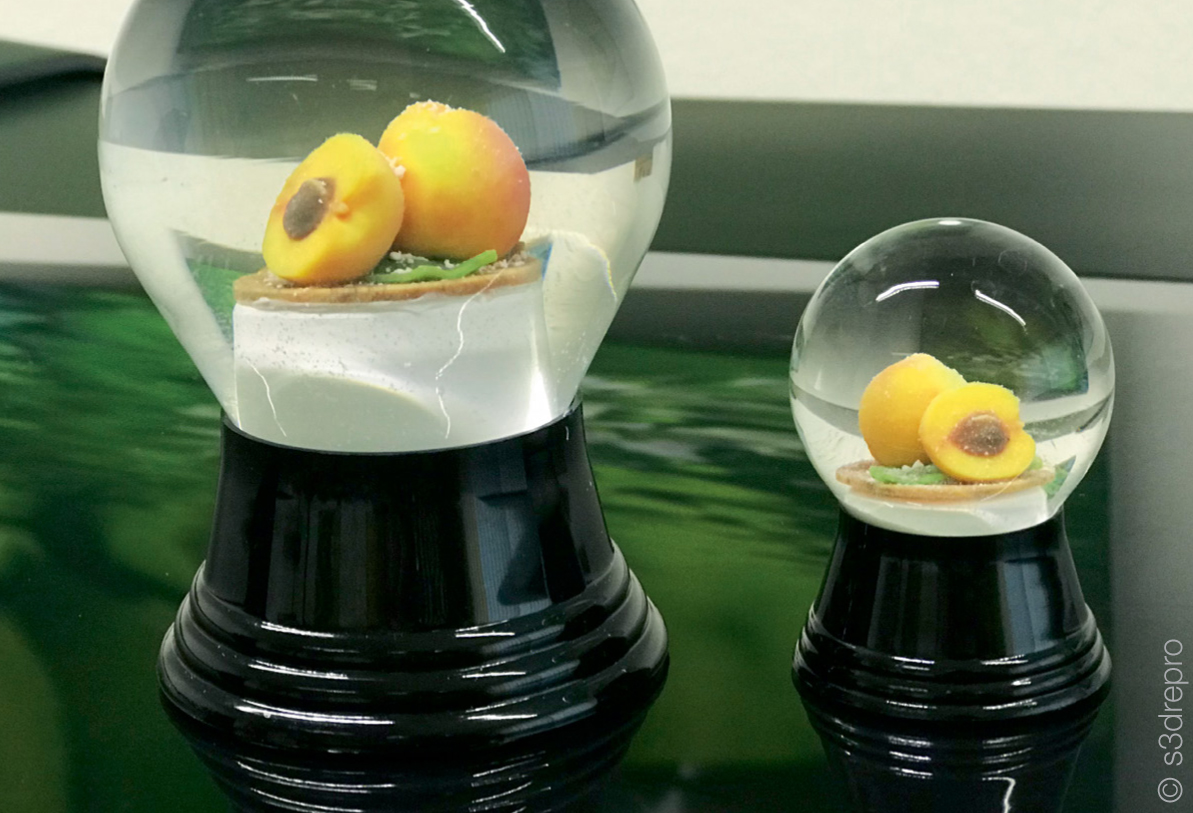

The challenge for snow globe figures isn’t just because of their very small size, but for the fact that they are enclosed in a glass sphere – which magnifies the small figures and details as if they were under a microscope. A large proportion of the snow globes that are produced are of people and products, and thus need to look realistic or mirror the real thing.

With the J750 capable of producing small, detailed, and complex models of up to 500,000 colors at high speed with a diverse range of materials, Schiner 3D Repro saw the potential in using it to fulfill customized one-off jobs or large orders.

The benefits include:

- Production time was reduced significantly up to 85% compared to other methods

- Models were able to be fabricated ultra-realistically with layer thickness as fine as 0.014mm

- Able to print in vivid colors with the ability to last longer because of the proven longevity of PolyJet materials

- GrabCAD Print software streamlines design-to-print workflow

The company frequently take in orders between 1 to 3,000 for various customers and therefore require fast turnaround times regardless of job size. The large build tray enables the fabrication of around 200 snow globe figurines, in one go, and in under 24 hours. This represented a huge saving in time of up to 85% compared to other manufacturing methods.

The company has been using the J750 for over 4 years now, and have been impressed with how the colors and materials are still looking as good as the day they were produced. All in all, the J750 has been a sound investment and asset to their business in delivering ultra-quality 3D printing at speeds that they cannot find elsewhere.